High quality raw materials

Imported high-quality springs are more fatigue-resistant, aluminum alloy spring seat snap ring assembly.

High-precision aluminum alloy flange is not easy to be damaged, and high-precision hook is not easy to be elastically empty due to abrasion.

Abrasion resistance of super-hard 6061 aluminum alloy casing, and the button is not easy to fall off by stretching process.

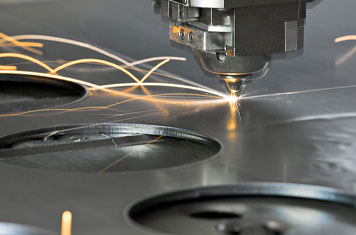

Precision machining technology

Adopt CNC machining center and other machine tools to refine the movement, and the rebound value is guaranteed.

Finely grind the spherical zero-setting screws to make the rebound firing smoother and smoother.

User friendly design

Silicone bracket for soft hand protection, more comfortable rebound operation.

Improved pointer design, easy to adjust friction and more stable.

Beautiful label and ruler are easy to read, and the hard oxidation treatment of the parts is beautiful and durable.

Multiple original imported dust-proof components, cleaner movement and longermaintenance period

High quality raw materials

Imported high-quality springs are more fatigue-resistant, aluminum alloy spring seat snap ring assembly.

High-precision aluminum alloy flange is not easy to be damaged, and high-precision hook is not easy to be elastically empty due to abrasion.

Abrasion resistance of super-hard 6061 aluminum alloy casing, and the button is not easy to fall off by stretching process.

Precision machining technology

Adopt CNC machining center and other machine tools to refine the movement, and the rebound value is guaranteed.

Finely grind the spherical zero-setting screws to make the rebound firing smoother and smoother.

User friendly design

Silicone bracket for soft hand protection, more comfortable rebound operation.

Improved pointer design, easy to adjust friction and more stable.

Beautiful label and ruler are easy to read, and the hard oxidation treatment of the parts is beautiful and durable.

Multiple original imported dust-proof components, cleaner movement and longermaintenance period

| Product Name | RH225-A Concrete Test Hammer

| RH225-B Digital Concrete Test Hammer

| RH20-A

| RH75-A Concrete Test Hammer  |

|---|---|---|---|---|

| LED Display | — — | ● | — — | — — |

| Screen dot matrix | — — | 265 x 64 | — — | — — |

| Net weight | 1 KG | 1.2 KG | 0.8KG | 0.9 KG |

| PC Software | — — | ● | — — | — — |

| bluetooth | — — | ● | — — | — — |

| Battery Power | — — | ● | — — | — — |

| Impact Energy | 2.207 J | 2.207 J | 0.196 J | 0.735 J |

| Calibration value of testing anvil | 80±2 | 80±2 | 74±2 | 74±2 |

| Compressive strength range | 10-70N/mm2 | 10-70N/mm2 | 2-15N/mm2 | 10-70N/mm2 |

| Name | Technical indicators |

|---|---|

Measuring range | 10~70 MPa |

Standard impact energy | 0.735J |

| Stretch length of impact spring | 75±0.3 mm |

Friction of pointer | 0.5 ± 0. 1 N |

Operating length of elastic tension spring | 61.5±0.3 mm |

Calibration value on testing anvil | 74±2 |

Components

1

1

2

2

3

3

4

4

5

5

1Brick test hammer

2Hand protector silicone hand rest

3A grinding stone

4One maintenance kit

5One injection-molded vibration-proof instrument box